SURGE (LIGHTNING) ARRESTOR

• GENERAL FEATURES

Electrical Power and Transmission system are affecting from abnormal high voltage due to surge or switching in transmission system, such type-high peak or crest waves (travelling waves) may cause flash over in the internal winding of equipment or may cause external flash over between the terminal (HV to ground) of the electrical equipment which may result in damage the equipment. Lighting arrester is the device which protect from the such abnormal condition during surges. This device diverts the abnormal high voltage to the ground without affecting the continuity of supply.

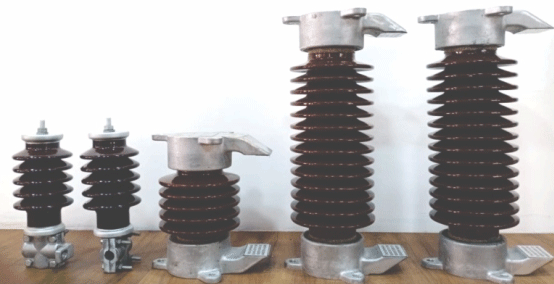

Distribution Class

- 9kV, 5kA Surge Arrester, Distribution Class

- 9kV, 10kA Surge Arrester, Distribution Class

Station Class

- 9kV, 10kA Sugar Arrester

- 30kV, 10kA Surge Arrester, Station Class-1

- 30kV, 10kA Surge Arrester, Station Class-2

• MANUFACTURING FACILITY

Under expansion plans a new state of the are unit with modern manufacturing facilities, our manufacturing infrastructure are 30,000 Sq. feet, which is facilities with epoxy resin vacuum casting plant (350 kG epoxy material handling capacity in one charge), 02 No. vacuum drying oven, oil filtration plant, 12 No. HV coil (Foil and Strip) winding machine (semi-Automatic),06 No. LV winding machine, instrument transformer / LA test & transformer testing panel with CT-VT test bridge, OVIT test panel, power analyzer, resistance meter, turns ratio meter & amp; DVDF generator. HV tester up to 100 kV, impluse generator 400 kVp, High current impulse generator & amp; Partial discharge test measurement system. we have 55 No. skill technician for winding, testing and and assembly. in house fabrication facility for dry transformer enclosure and qualitative work, our work shop is facilitate with laser cutting machine, CNC banding machine & stud welding machine.

• Quality Control (Quality certified to ISO 9001)

Our quality control team involves product design, manufacture, testing & supply of transformer according to their relevant, IEC / IS standards to meet the customer requirement and ensuring following :

- Consistently meeting the customer requirements.

- Continue Improvement of Quality.

- On Time delivery.

- Better services after dispatch sale and services.

Before the all products (Instruments Transformer/ LA & amp; Dry type CRT Transformer) are supplied to the customer, they are individually inspected and must pass the acceptance tests and, where necessary, type tests, if these are requested in the order phase. At the end of the acceptance testes a specific inspection note is affixed to each product. Both the ordering company and any final customer can reserve the right to be present at the inspection in the test room and, on prior notification, can make inspection visits before and during the carrying out of the order.